Help and Information

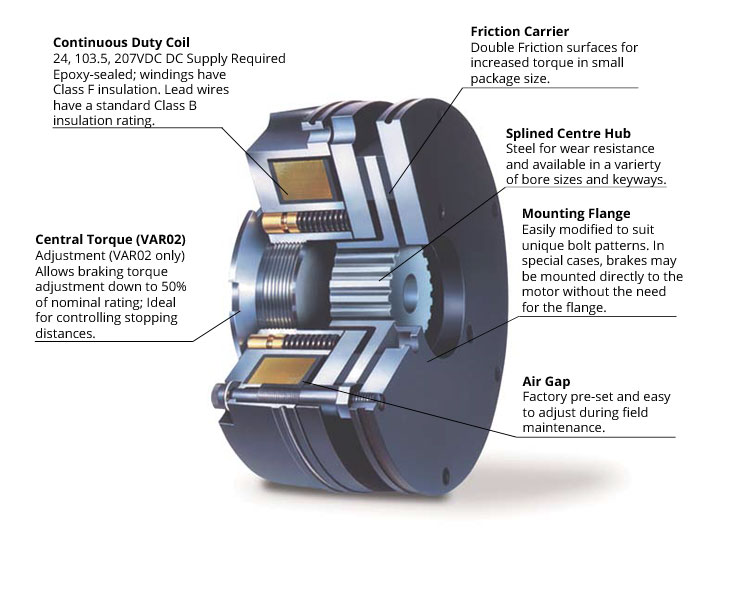

ERD Brake Parts

Features

- Spring-set design holds the load in place when voltage is removed from the brake

- Dynamic friction material can stop loads from motor speeds up to 3600 RPM

- Few moving parts mean quiet operation

- Lead and Asbestos free, dynamic friction material is suited for high cycle rates

- Adjustable air gap for ease of service and long life in the field

- Variety of voltages available

- Simple DC Control (or AC with available rectifiers)

- Low power requirements for energy savings

- Torque capacities from 5Nm to 300Nm

- Bi-directional stopping capability

- Low inertia rotating parts

- Splined hub for quiet operation

- Metric bore sizes

Options

The optional Manual Release allows the brake to be released by hand; Ideal for lowering suspended loads. The optional Dust Cover shields the brake actuation systems from external dust and debris.

By applying voltage to the ERD, an electromagnetic field is created which causes the armature plate to pull-in against helical compression springs, thus releasing the brake. When power is removed, the springs force the armature to compress the friction carier against the mounting flange, thus stopping and holding the load. Fully dynamic friction material on the carrier allows for repeated braking cycles from full motor speed with no torque fade.

Dual Purpose Engagement Brakes

ERD Series Brakes are dual purpose brakes that can perform static holding as well as dynamic stopping functions.

These brakes are designed to safely keep the load in position in the event of a power or motor failure, whether intentional or accidental.

An optional manual release allows the operator to safely move the load even when no power is available.

Torque adjustment of up to 50% of the dynamic capability is also available. (VAR02)

ERD Brakes must be fitted by a Competent Engineer and Qualified Electrician for electrical connections

ERD Brake Types

VAR 00 Fixed Torque none adjustable

VAR 02 Adjustable Torque up to 50% less of nominal torque Brakes are supplied adjusted to nominal torque.

Rotor – Friction Disc Carrier

All sizes are supplied with a metallic version; sizes 5 and 10 can be supplied with a synthetic version on request.

The Hub has to be selected to suit the diameter of the mounting shaft and requires a keyway to stop rotation. Several standard sizes are offered and if these don’t match a pilot bored hub is available to be machined to your own dimension. (Please note we do not offer a machining service)

Mounting Flange

If the mounting surface does not meet the following specifications:

- Cast iron or steel surface

- Hardness 150 HB

- Roughness 3,2 Ra (125 micro inches)

- Flatness 0,05 mm

Then an intermediate or thick friction flange has to be used. (Note the thin friction flange pressed steel type is discontinued use intermediate to replace)

Thick Friction Flange – 5Nm to 300Nm has 3 holes for directly bolting to the mounting face and three more tapped holes for the rest of the unit to bolt too.

Intermediate Friction Flange - 5Nm to 35Nm has 3 clearance holes for the unit to bolt straight through to the mounting surface.

Full Wave Rectifier - Brake requiring correct DC Supply. 220/240VAC Input supplies 190VDC Output. 110VAVC Input supplies 96VDC Output.

Half Wave Rectifier - Brake requiring correct DC Supply. 380/415VAC Input supplies 190VDC Output. 220/240VAVC Input supplies 96VDC Output.

Dust Cover - If you are using the brake in a clean environment or the surrounding atmosphere is loaded with dust or humidity we recommend the use of a dust cover.

Hand Release VAR 02 Only Hand Release allows the brake to be released without the unit being energised.

The short mounting screw kit should be ordered for the thick flange .The thick flange is for mounting on the external diameter threaded holes.

The long mounting screw kit should be ordered for the intermediate flange and is for mounting through the thin flange on external diameter or if ordered separately for direct mounting without flange.

ERD Brakes must be fitted by a Competent Engineer and Qualified Electrician for electrical connections

Electrical connection

ERD brakes have to be supplied with direct current and are factory fitted with 400mm long wires. The polarity does not affect operation. (See Service Manual for full details)

Detector Kit and Connection Kit are available on request please contact Transdrive sales desk.

Warner Electric Direct

Warner Electric Direct